Software

To ensure every prosthesis fits comfortably and functions reliably, we rely on a precise and streamlined digital workflow. This process allows us to create customized devices quickly while maintaining a high level of accuracy.

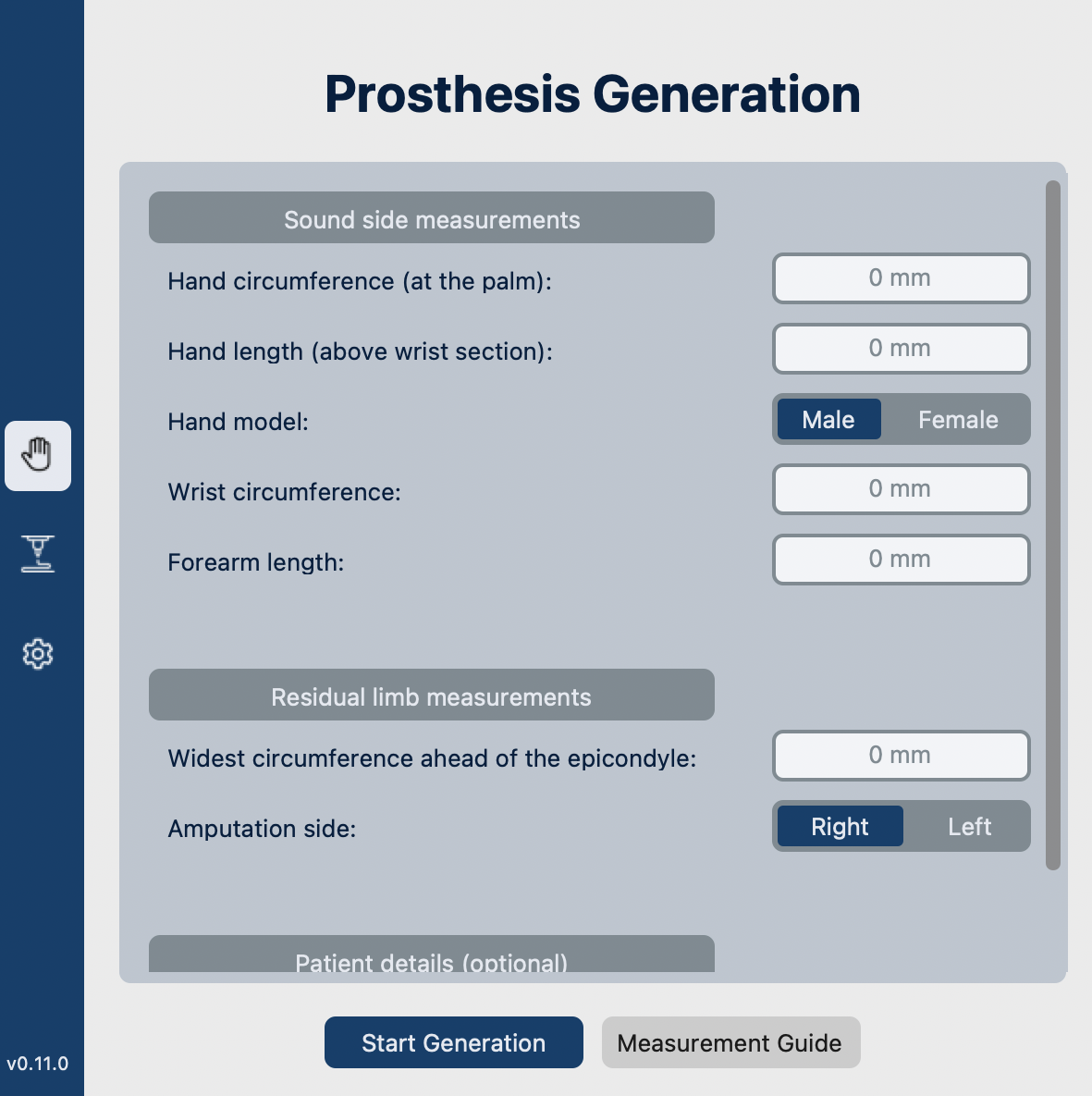

We begin by taking detailed measurements of both the amputated limb and the patient’s healthy arm or leg. These measurements help capture the individual’s natural proportions and ensure that the final prosthesis offers a secure and comfortable fit. Our specially developed software processes this data and automatically generates a prosthesis model in the correct size and geometry. Once the digital model is finalized, it is sent directly to the 3D printer, enabling a fast, efficient, and highly personalized production process.