What we do

Affordable, Custom-Fit Prosthetics Made for Real-World Needs

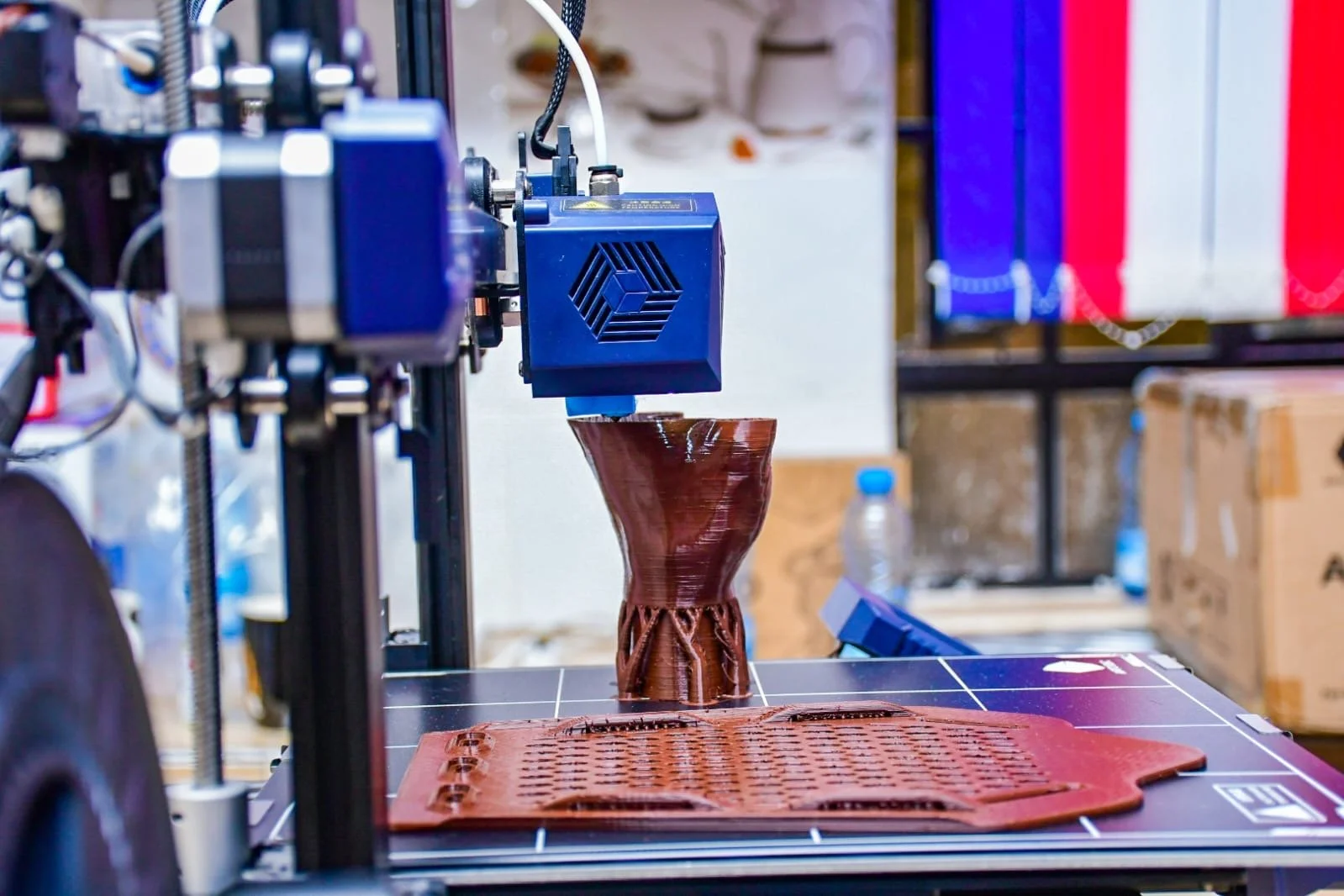

Our 3D-printed prostheses combine smart engineering with simple, user-focused design. Each device is lightweight, durable, and individually tailored—making high-quality mobility support accessible where traditional solutions are often out of reach.

Our three offers

-

Arm prosthesis

The 3D-printed forearm prosthesis combines a natural-looking cosmetic hand with a lightweight, ventilated support plate that is shaped to fit the user comfortably. Simple elbow straps secure the prosthesis in place, while a soft inner lining reduces pressure for longer wear. Designed to be affordable and quickly adaptable, it offers people with forearm amputations greater independence and dignity.

-

Leg prosthesis

The 3D-printed leg prosthesis features a soft silicone liner for comfort, a precisely fitted 3D-printed socket, and an adjustable aluminum tube that ensures stability and proper leg length. Its lightweight, spring-like foot provides reliable everyday support. With its modular design, it is easy to produce, repair, and adapt - making it a practical mobility solution for people in low-income regions and areas with limited healthcare access.

-

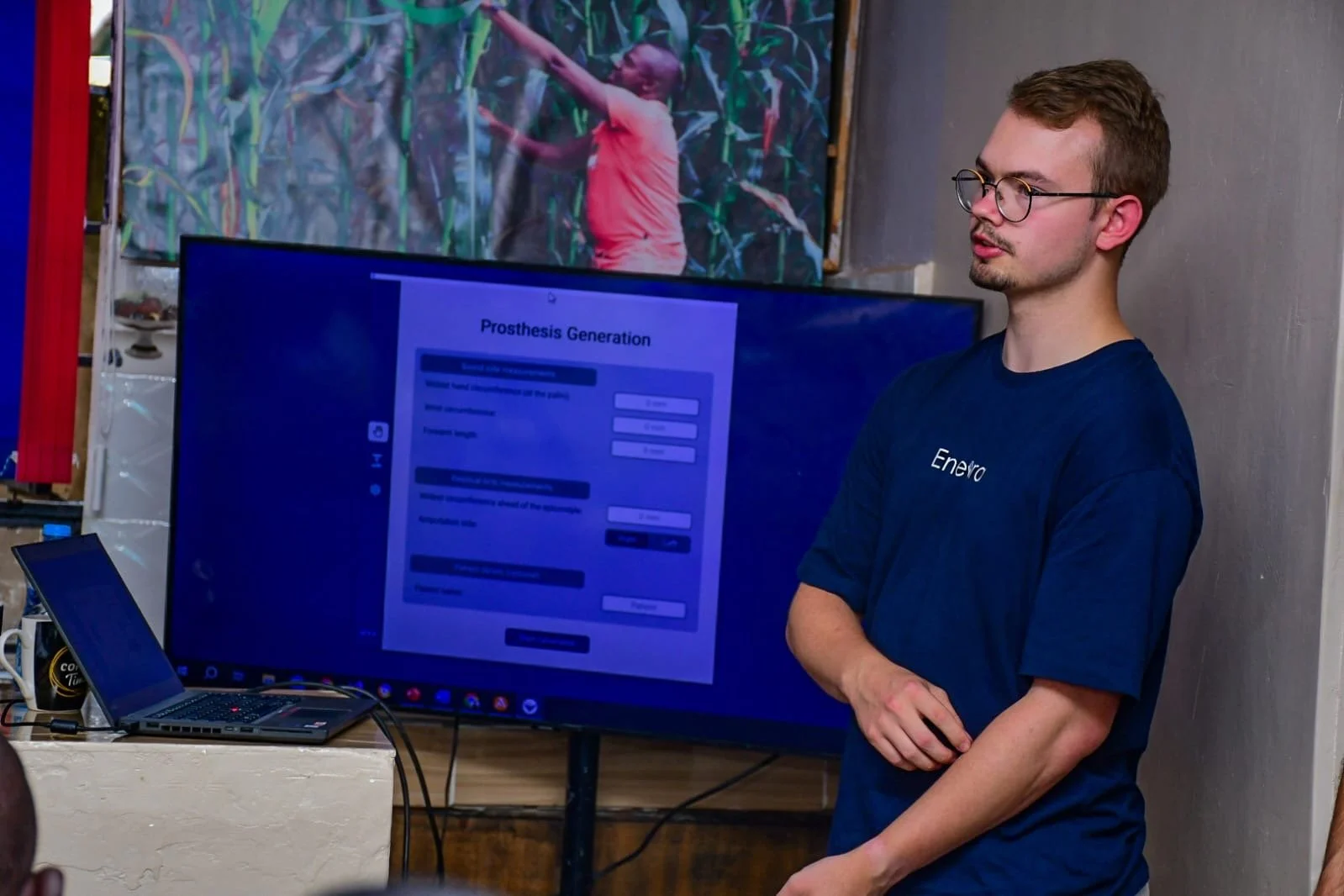

Software

We take key measurements of both the amputated limb and the healthy side. Our custom software uses this data to create a prosthesis model in the correct size, which can then be sent directly to the 3D printer. This ensures a fast, efficient, and personalized fit for every user.

Our Process

-

We connect with medical organizations and orthopedic workshops to understand their needs and explore how our prosthetic solutions can support their work. Through initial calls and assessments, we jointly determine the best way to implement our system locally.

-

Our team travels on-site with all necessary equipment to train local technicians in using our software, production workflow, and 3D-printing technology. Over the course of intensive workshops, participants learn every step required to independently produce our prostheses.

-

Together with the local team, we manufacture the first prostheses on-site and fit them directly to patients, ensuring proper comfort and functionality. By the end of this phase, the local workshop is fully capable of producing and delivering prostheses on its own.

-

We provide ongoing support by guiding the team in prosthesis maintenance, patient follow-up, and long-term care. Additionally, we supply necessary materials and technical advice to guarantee consistent, high-quality production.